I. Introduction

One of the most persistent misconceptions in bathroom fixture specification is that “all stainless steel drains are essentially the same.” This dangerous oversimplification leads to premature product failure and unnecessary replacement costs, particularly in demanding environments.

The truth is that material selection—specifically choosing between 304 and 316 stainless steel—represents one of the most critical decisions in shower drain specification. With bathroom drainage systems exposed to consistent moisture, chemical cleaners, and varying water qualities, the stainless steel grade directly determines product longevity, maintenance requirements, and ultimately, customer satisfaction.

For quality control professionals, understanding the metallurgical properties of different stainless steel grades is not merely academic—it translates directly to product performance, warranty claim rates, and brand reputation. The difference between a drain that maintains its integrity for 5 years versus 20+ years often comes down to this fundamental material decision.

In this comprehensive analysis, we’ll examine the critical differences between 304 and 316 stainless steel for shower drain applications, provide data-driven selection guidelines, and equip quality control personnel with the technical knowledge required to make optimal material specifications.

II. Understanding Stainless Steel for Bathroom Applications

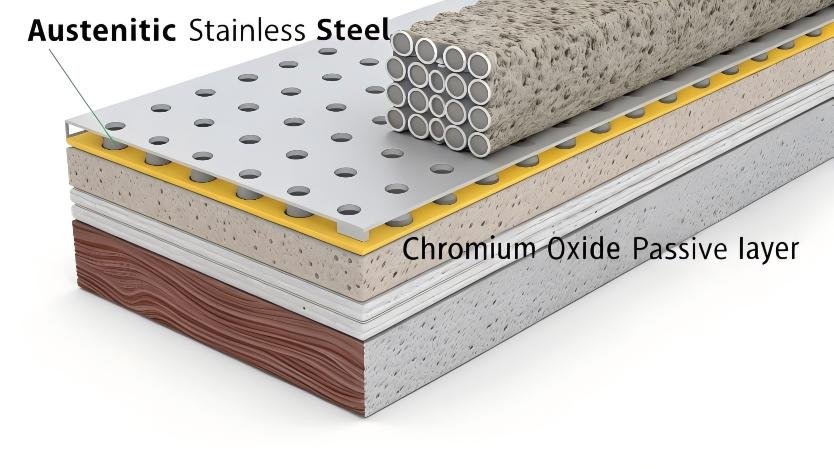

Stainless steel has become the material of choice for premium bathroom drainage systems due to its unique combination of properties ideally suited to wet environments. The material’s core advantage lies in its formation of a self-healing chromium oxide layer that prevents oxidation and corrosion when exposed to oxygen.

1.The Chemistry Behind Corrosion Resistance

The corrosion resistance of stainless steel is primarily determined by three key elements:

- Chromium (Cr): The essential element that forms the passive oxide layer, with a minimum of 10.5% required for classification as stainless steel

- Nickel (Ni): Enhances formability and provides resistance to reducing acids

- Molybdenum (Mo): Significantly improves resistance to chloride attack and pitting corrosion

Environmental factors in bathrooms create particularly demanding conditions for metals:

- Frequent moisture exposure with cycles of wet and dry

- Chemical exposure from cleaning agents (particularly chlorine-based products)

- Potential galvanic corrosion from contact with dissimilar metals

- Temperature fluctuations that can accelerate corrosion processes

2.Stainless Steel Classification System

The numeric designation system for stainless steel follows specific conventions:

- 300 series: Austenitic stainless steels (non-magnetic, containing nickel)

- 400 series: Ferritic and martensitic stainless steels (magnetic, containing little or no nickel)

For bathroom fixtures, the 300 series is almost exclusively used due to superior corrosion resistance and formability.

III. 304 Stainless Steel: The Popular Choice

1.Chemical Composition and Properties

304 stainless steel (sometimes referred to as 18/8) contains:

- 18-20% Chromium

- 8-10.5% Nickel

- <0.08% Carbon

- Trace elements including manganese and silicon

From a mechanical standpoint, 304 grade offers:

- Tensile strength: 515 MPa

- Yield strength: 205 MPa

- Elongation: 40%

- Hardness: 92 HRB (Rockwell B)

These properties provide excellent formability for manufacturing complex drain designs while maintaining structural integrity under typical bathroom loads.

2.Corrosion Resistance Profile

In standard bathroom environments, 304 stainless steel demonstrates:

- Excellent resistance to:

- General atmospheric corrosion

- Most household cleaning chemicals

- Organic acids and alkaline solutions

However, limitations become apparent when exposed to:

- Chloride concentrations exceeding 200 ppm

- Persistent high humidity (>80% RH) combined with warm temperatures

- Regular use of chlorine-based cleaners

- Lack of regular cleaning allowing mineral buildup

Under controlled testing, 304 stainless typically shows first signs of pitting after 500-750 hours in salt spray testing (ASTM B117) in standard bathroom conditions.

3.Cost Considerations

304 stainless steel typically costs 15-25% less than 316 grade for comparable drain products. On average, retail price differences range from $15-40 for residential drains, with larger commercial units showing proportionally greater differences.

Long-term value analysis indicates that for standard bathroom environments with proper maintenance, 304 stainless steel drains maintain functional and aesthetic integrity for 10-15 years—representing excellent lifecycle cost for most applications.

4.Ideal Application Scenarios

304 stainless steel is optimally suited for:

- Residential bathroom drains in non-coastal environments

- Areas with soft or moderately hard water

- Settings where regular cleaning maintenance is established

- Indoor applications with controlled humidity levels

- Projects with moderate budget constraints where performance cannot be compromised

IV. 316 Stainless Steel: The Premium Alternative

1.Chemical Composition and Enhanced Properties

316 stainless steel’s distinctive formulation includes:

- 16-18% Chromium

- 10-14% Nickel

- 2-3% Molybdenum

- <0.08% Carbon (or <0.03% in 316L)

This composition results in mechanical properties comparable to 304 grade but with significantly enhanced corrosion resistance:

- Tensile strength: 515 MPa

- Yield strength: 205 MPa

- Elongation: 40%

- Hardness: 95 HRB (slightly higher than 304)

The critical difference is the addition of molybdenum, which substantially improves resistance to chloride attack—the primary failure mode for shower drains.

2.Superior Corrosion Resistance

Laboratory and field testing demonstrate 316 stainless steel’s superior performance:

- Resists chloride concentrations up to 1000 ppm

- Maintains integrity in salt spray tests for 1000+ hours (ASTM B117)

- Withstands prolonged exposure to chlorinated water and cleaning agents

- Shows 5-10x greater resistance to pitting corrosion in coastal environments

Research data indicates that in high-humidity coastal environments, 316 stainless steel shows minimal degradation after 15 years, while equivalent 304 products typically require replacement after 3-5 years.

3.Premium Pricing Structure

316 stainless steel products command a premium of 20-30% over equivalent 304 grade products. For standard linear shower drains, this typically translates to:

- Small residential units: $25-50 additional cost

- Commercial-grade drains: $75-150 additional cost

- Custom architectural drains: $150-300+ additional cost

While the initial investment is higher, ROI analysis demonstrates that in harsh environments, the elimination of premature replacement makes 316 the more economical choice within a 5-7 year timeframe.

4.Ideal Application Scenarios

316 stainless steel is the definitive choice for:

- Coastal properties within 50 miles of saltwater

- Bathrooms with poor ventilation or persistent high humidity

- Applications using hard or mineral-rich water

- Commercial installations with intensive cleaning protocols

- Luxury residential properties where long-term performance is prioritized

- Settings where maintenance may be irregular or less thorough

V. Side-by-Side Comparison

1.Comprehensive Comparison Table

| Property | 304 Stainless Steel | 316 Stainless Steel |

| Corrosion Resistance (1-10) | 7 | 9 |

| Chloride Resistance | Moderate | Excellent |

| Average Cost Premium | Baseline | +20-30% |

| Typical Pricing (Linear Drain) | $80-200 | $100-260 |

| Expected Lifespan (Standard Environment) | 10-15 years | 15-25+ years |

| Expected Lifespan (Coastal/Harsh) | 3-5 years | 12-20 years |

| Maintenance Requirements | Regular | Moderate |

| Magnetic Properties | Slightly Magnetic | Non-magnetic |

2.Visual Degradation Comparison

Over time, the appearance of stainless steel drains changes based on grade and environment:

304 Stainless Steel:

- After 2-3 years: Potential light spotting in high-moisture areas

- After 5 years: Possible pitting visible on close inspection in harsh environments

- After 7-10 years: Surface roughening and visible corrosion in coastal settings

316 Stainless Steel:

- After 5 years: Typically maintains original appearance with proper cleaning

- After 10 years: Minimal surface changes, possibly slight dulling

- After 15+ years: May develop subtle patina but rarely exhibits pitting or corrosion

The most significant difference appears in resistance to staining from mineral deposits, with 316 demonstrating substantially better resistance to the etching effects of mineral accumulation.

VI. Decision Guide: Making the Right Choice

1.Budget Considerations

The premium cost of 316 stainless steel is justified when:

- Project lifetime expectations exceed 10 years

- Replacement costs (including labor) would exceed 2.5x the initial installation cost

- Warranty claims would create significant brand reputation damage

- The drain is inaccessible or difficult to replace

- The total drain cost represents <5% of the total bathroom budget

For value engineering, consider:

- Hybrid solutions using 316 for critical components and 304 for secondary elements

- Limiting 316 specification to high-moisture areas while using 304 for less exposed areas

- Evaluating total lifecycle costs rather than initial procurement costs

2.Environmental Assessment

Geographic and environmental factors dictate optimal material selection:

Geographic Location:

- Coastal (within 50 miles of ocean): 316 stainless steel strongly recommended

- Urban/Industrial areas with high pollution: 316 preferred

- Rural inland locations: 304 typically sufficient

Bathroom Conditions:

- Poor ventilation: Favors 316

- Steam shower units: 316 recommended

- Window/fan ventilated spaces: 304 generally adequate

- Water hardness >10 grains: 316 offers superior performance

3.Usage Patterns

Daily use patterns significantly impact material requirements:

- High-occupancy households (4+ residents): Higher usage favors 316

- Properties with frequent guests (vacation rentals): 316 recommended

- Cleaning regimen using chlorinated products: 316 essential

- Sporadic usage with periods of non-use: 316 reduces maintenance requirements

4.Installation Context

Project-specific factors to consider:

- New construction allows for optimal material selection without constraints

- Renovations may require matching existing fixtures or accommodating space limitations

- Integration with other bathroom materials may dictate grade selection based on galvanic compatibility

- Expected renovation cycles should align with material longevity expectations

VII. Maintenance and Care

1.Cleaning Best Practices for Each Grade

For 304 Stainless Steel:

- Clean weekly with non-abrasive, non-chlorinated cleaners

- Immediately rinse after exposure to high-chloride products

- Quarterly deep cleaning to remove mineral deposits

- Use vinegar solution (1:3 with water) for mineral deposit removal

For 316 Stainless Steel:

- Can withstand bi-weekly cleaning schedules

- Moderate tolerance to chlorinated cleaners (though avoidance still recommended)

- Bi-annual deep cleaning typically sufficient

- Superior resistance to cleaning chemical damage

2.Avoiding Damage

Both grades benefit from these protective practices:

- Avoid steel wool or abrasive cleaning tools

- Prevent prolonged contact with carbon steel tools that can cause contamination

- Keep drain surfaces dry when not in use when possible

- Eliminate standing water that can concentrate minerals

- Avoid silver cleaners and bleaches containing chlorides

3.Extending Lifespan

To maximize service life:

- Apply annual wax-based protective treatments to create additional barrier protection

- Polish according to grain direction to maintain surface integrity

- Address minor corrosion immediately with specialized stainless steel cleaners

- Consider electrolytic cleaning for severe cases of corrosion

- Install water softeners in areas with mineral-rich water

VIII. Market Overview: Popular Products

Leading Manufacturers

The stainless steel drain market features several distinguished manufacturers:

- ACO– Known for commercial-grade products with rigorous material certification

- BLÜCHER– Specializes in high-end 316 stainless drains with architectural designs

- Geberit– Offers extensive testing documentation for material performance

- Infinity Drain– Features both 304 and 316 options with detailed specification sheets

- California Faucets– Luxury residential focus with premium 316 offerings

Quality differences correlate strongly with price points, primarily in:

- Material thickness (ranging from 1.5mm to 3mm)

- Weld quality and finishing techniques

- Surface treatment consistency

- Supporting documentation and testing certification

Design Innovations

Modern stainless steel drain design trends include:

- Minimalist linear drains with nearly invisible profiles

- Custom pattern grates for architectural statement pieces

- Integrated lighting systems requiring superior corrosion resistance

- Tile-insert drains that conceal the drainage system entirely

- Smart drains with electronic monitoring requiring extended service life

IX. Frequently Asked Questions

Q1: Will 304 stainless steel rust in my shower?

Under proper maintenance conditions in standard environments, 304 stainless steel should not develop red rust. However, it may develop surface discoloration or pitting in high-moisture, high-chloride environments. What appears as “rust” is typically either surface contamination or localized corrosion that can be addressed with proper cleaning.

Q2: Is the extra cost of 316 stainless steel worth it?

For coastal properties, commercial applications, or any setting with aggressive chemical exposure, the additional 20-30% cost is justified by a typical doubling of service life. For standard residential bathrooms with good ventilation and regular maintenance, 304 stainless often provides adequate performance at a lower cost point.

Q4: How can I tell what type of stainless steel my current drain is made from?

Without specialized equipment, definitive identification is challenging. However, 316 is typically specified on product documentation and packaging. A magnet will be slightly attracted to 304 but show minimal attraction to 316. For existing installations, look for evidence of pitting in high-exposure areas—early pitting suggests 304 grade.

Q5: Can I install a stainless steel drain myself?

Professional installation is recommended for both grades, particularly for linear drains that require precise slope calculations and waterproofing integration. Improper installation can create water traps that accelerate corrosion regardless of material grade.

Q6: How long should a quality stainless steel drain last?

A properly specified and maintained 304 stainless steel drain should perform for 10-15 years in standard environments. A 316 stainless steel drain should maintain integrity for 15-25+ years, even in more demanding conditions. Premature failure typically indicates either incorrect specification or improper maintenance.

X. Conclusion

The selection between 304 and 316 stainless steel for shower drains represents a critical quality control decision with significant implications for product performance and customer satisfaction. While both materials offer excellent corrosion resistance compared to alternative materials, their performance differences in chloride-rich environments are substantial.

For standard residential bathrooms with good ventilation, regular maintenance, and moderate water mineral content, 304 stainless steel provides an excellent balance of performance and value. However, for coastal locations, poorly ventilated spaces, or applications where extended service life is prioritized, 316 stainless steel’s superior corrosion resistance justifies its premium pricing.

Quality control professionals should establish clear specification guidelines based on:

- Environmental exposure assessment

- Expected service life requirements

- Maintenance protocol realities

- Total lifecycle cost calculations

We encourage all quality managers to develop a systematic material selection process that accounts for both the technical requirements and the practical usage conditions of the end product. Remember that the true cost of a drainage system includes not just initial procurement, but also potential replacement costs, warranty claims, and brand reputation implications.

By selecting the appropriate stainless steel grade for each specific application, you ensure optimal performance, customer satisfaction, and long-term value that will reflect positively on your brand’s commitment to quality.