- Understanding Cast Iron Plumbing Challenges

- Tip 1: Choose the Right Connection Method

- Tip 2: Preparation and Cleaning of the Hub

- Tip 3: Precise Cutting Techniques

- Tip 4: Selecting the Optimal Shower Drain Type

- Tip 5: Ensuring Water-Tight Sealing

- Tip 6: Testing and Quality Control

- Installation Summary Table

- Frequently Asked Questions

Understanding Cast Iron Plumbing Challenges

Before you begin to install shower drain to cast iron pipe, it is essential to understand the material properties. Cast iron pipes are heavy, prone to internal scaling, and brittle. Unlike PVC, which can be easily cut with a handsaw and glued, cast iron requires specialized tools like snap cutters or reciprocating saws with diamond-grit blades. The primary goal when you install shower drain to cast iron pipe is to create a transition that accounts for the different expansion rates and surface textures of the old metal and the new plastic or stainless steel drain components.

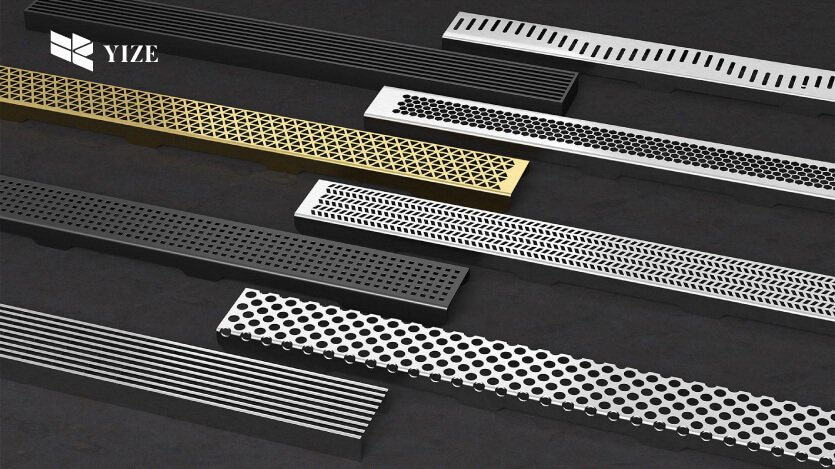

Noahhometech Bathroom Drainage Experts

As a leading shower drain manufacturer, we specialize in high-quality, visually striking drainage solutions for bathrooms, hotels, and commercial spaces. Our complete OEM and ODM services include ultra-thin linear drains, square drains, vertical drains, and fully customized shower systems, made from 304 stainless steel with durable PVD finishes.

Tip 1: Choose the Right Connection Method

The most critical decision when you install shower drain to cast iron pipe is selecting the transition fitting. Historically, plumbers used molten lead and oakum, but this is outdated and hazardous. Today, there are two primary professional methods:

The No-Hub Coupling (Fernco)

A no-hub coupling consists of a neoprene rubber sleeve and a stainless steel shield with clamps. This is the preferred method for most DIYers and professionals alike because it allows for flexibility. When you install shower drain to cast iron pipe using this method, the rubber absorbs vibrations and prevents the connection from cracking over time.

The Compression Gasket

Commonly referred to as a donut, this heavy-duty rubber gasket is pushed into the hub (the flared end) of the cast iron pipe. The new PVC or stainless steel drain pipe is then lubricated and forced into the gasket, creating a mechanical seal. This is ideal if the existing cast iron hub is still in good condition.

Tip 2: Preparation and Cleaning of the Hub

You cannot install shower drain to cast iron pipe successfully if the mounting surface is covered in rust, debris, or old lead. Cast iron pipes often build up a layer of oxidation that creates an uneven surface. Use a wire brush or a drill-mounted wire wheel to scrub the interior and exterior of the pipe where the connection will be made.

If you are using a compression gasket, the inside of the hub must be smooth. Any pits or ridges in the metal can lead to slow leaks that are difficult to detect once the shower pan is installed. Taking twenty minutes to properly clean the pipe ensures the longevity of your install shower drain to cast iron pipe project.

Tip 3: Precise Cutting Techniques

When you prepare to install shower drain to cast iron pipe, the cut must be as square (90 degrees) as possible. If the cut is jagged or angled, the coupling will not sit properly, leading to a weak point in the system.

For horizontal runs, use a snap cutter if space allows. In tight quarters, such as between floor joists, a reciprocating saw with a carbide-tipped blade is more effective. Always wear eye protection and a mask, as cutting cast iron produces fine metallic dust and sparks. A clean cut is the foundation of a successful attempt to install shower drain to cast iron pipe.

Tip 4: Selecting the Optimal Shower Drain Type

The hardware you choose determines the efficiency of the drainage system. Noahhometech offers a variety of solutions tailored for professional installations. When you install shower drain to cast iron pipe, consider the depth of your floor and the desired aesthetic.

Linear Drains vs. Square Drains

For modern, curbless showers, a custom Ultra-Thin Type Shower Drain or a custom Linear Wall Shower Drain is ideal. These designs allow for a single-slope floor, which simplifies the tiling process. If you are working with a traditional center-drain layout, a custom Square Bathroom Drain provides a classic look with superior 304 stainless steel durability. Matching a high-quality Noahhometech drain with a robust cast iron stack ensures a premium end-user experience.

Tip 5: Ensuring Water-Tight Sealing

Sealant is your second line of defense. When you install shower drain to cast iron pipe, the mechanical connection (the clamp or gasket) does the heavy lifting, but applying a plumbing-grade lubricant or silicone in specific areas can aid the process.

If using a donut gasket, apply a generous amount of pipe lubricant (sometimes called duck butter) to the outside of the PVC pipe. This allows the pipe to slide into the tight rubber gasket without tearing it. For the drain body itself, always use 100% silicone sealant or a high-quality plumber’s putty between the drain flange and the shower base to prevent surface water from bypassing the drain entirely.

Tip 6: Testing and Quality Control

Never close up a floor or pour a concrete pan until you have tested the system. To test your install shower drain to cast iron pipe project, use a test plug to block the drain line downstream. Fill the shower base or the drain pipe with water and let it sit for at least 24 hours.

Check for moisture around the no-hub coupling or the compression gasket. Even a single drop of water indicates a failure that will eventually lead to wood rot or mold. Professionalism in plumbing means verifying every connection before it becomes inaccessible.

Installation Summary Table

| Component | Best Material | Installation Note |

|---|---|---|

| Transition Coupling | Shielded No-Hub Rubber | Tighten to 60 inch-pounds of torque. |

| Drain Body | 304 Stainless Steel | PVD finish recommended for durability. |

| Pipe Lubricant | Water-based lubricant | Essential for gasket/donut seals. |

| Cutting Tool | Carbide/Diamond Blade | Ensure square cuts for better sealing. |

Why Choose Noahhometech for Your Project?

At Noahhometech, we understand that the transition to legacy systems requires precision-engineered components. When you install shower drain to cast iron pipe, using a cheap plastic drain body can lead to threading issues or thermal expansion cracks. Our 304 stainless steel drains are designed to withstand the rigors of commercial and residential use.

Our custom Odor-Resistant Type Shower Drain is particularly useful in older buildings where sewer gas backflow can be an issue due to aging vent stacks. Furthermore, our custom Insert Wall Shower Drain provides a sleek, hidden aesthetic that adds value to any renovation. We provide globally recognized certifications, ensuring that our products meet the highest safety and performance standards.

Frequently Asked Questions

Can I glue PVC directly to cast iron?

No. PVC cement only works on specific plastics. To install shower drain to cast iron pipe, you must use a mechanical transition like a shielded coupling or a compression gasket.

How do I know if my cast iron pipe is too corroded?

If the pipe wall thickness is significantly reduced or if you can flake off large chunks of rust with a screwdriver, the pipe may need to be replaced further down the line before you install shower drain to cast iron pipe.

What is the benefit of a linear drain over a square drain?

Linear drains, like the Noahhometech custom Strip Vertical shower Drain, allow for larger format tiles and a single-slope floor, reducing the number of grout lines where mold can grow.

Do I need a professional to install shower drain to cast iron pipe?

While it is possible for a skilled DIYer, the weight and difficulty of cutting cast iron often make it a job for a professional plumber to ensure code compliance and leak-proof results.

Conclusion

Successfully completing an install shower drain to cast iron pipe task requires patience, the right tools, and premium hardware. By following these six tips—selecting the right coupling, preparing the hub, cutting accurately, choosing high-quality Noahhometech drains, sealing properly, and testing rigorously—you can bridge the gap between mid-century durability and modern luxury.